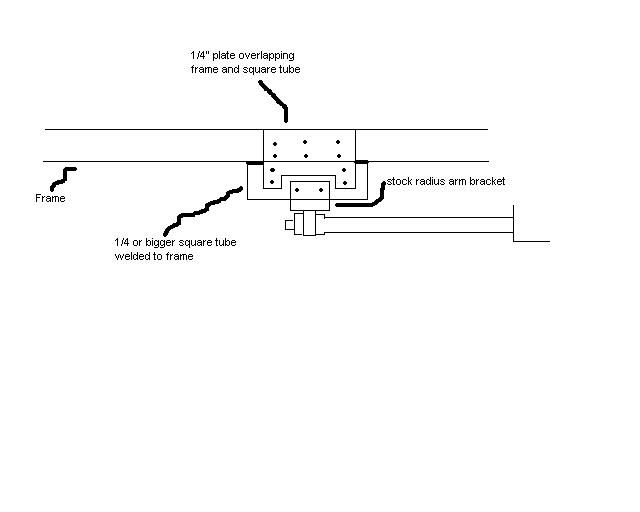

and a picture of a arm on a Bronco, not my truck

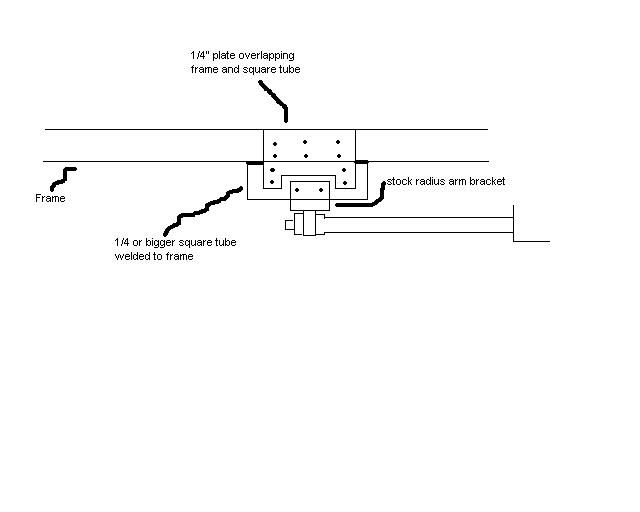

and here is my very rough sketch of an idea on how Im going to drop the brackets.

Ill update tomorrow as I get the metal and start welding

Moderator: FORDification

Im probably going to be taking it to a shop to get it welded, not sure yet, dont matter right now, I have a long ways to go, welding the extension on is the last thing im goint to do.4x4_Welder wrote:Preheat to 150º minimum, 300º maximum interpass, and use 8018 or 80s filler material. The arms are a high chrome alloy, and if you use 7018/70s or 60 series rods, there is a very good chance the welds will fail. 8018 rods and 80s wire, as well as temp sticks are available at most weld shops.

Please don't try to do this with a 110 mig, use stick or tig.