It's amazing how this kind of curveball gets thrown.

I have a 72 with 6200 GVWR, it's an F250 Custom with 12.125 x 2.0 drum front brakes.

On the drag link or centerlink, the longest of the three steering related arms, there is one part number for 6900,7500,8100 GVWR trucks and another part number for 6200 trucks. On the 69-8100 versions the balljoints studs at either end stick out of the bar in opposite directions.

On the 6200 version they stick out in the same direction. It appears all pre-70 trucks no matter the GVWR use one part number in which the balljoint studs stick out in the same direction and the bar itself is straighter overall than the 70+ (certain serial numbers in 70, the changeover year).

The strange thing is it leads me to believe based on the 69-8100 GVWR part I just purchased that the balljoint stud for the right steering knuckle would have to bolt down from above the knuckle as opposed to up from below like everything else I've seen on these trucks. The end of the drag link that comes mates to the pitman arm appears to be oriented to come up from the bottom as I would expect. If not, the pitman side would have to come down from the top, but I doubt I have this confused based on analysis of my own pics of both my complete 69 and 72 front ends sitting on the floor together. Anyone have an explanation or able to get a pic or two for me? I'm not sure why the difference.

I'm in the middle of a swap and want to get the right part to a powder coater. The price for the 6200 GVWR part is sky high or unavailable. I'm tempted to just purchase a 1969 part and use it with my 72 power steering pitman arm instead of trying to put all 72 steering parts with 69 dual piston disc brake knuckles. The opposite pointing balljoint studs seems like a zinger to me. Any help or even a peek under your truck and a report back would be appreciated.

Thanks

Chris here, or pm or cbizzme@yahoo.com

Anyone have a 70 - 72 F250 2wd with 6900,7500 or 8100 GVWR?

Moderator: FORDification

-

ChrisB

- New Member

- Posts: 73

- Joined: Thu Jul 28, 2005 6:57 pm

- Location: Southern California

-

fordman

- 100% FORDified!

- Posts: 22329

- Joined: Sun Aug 28, 2005 8:17 pm

- Location: Kansas, Ottawa

- Contact:

Re: Anyone have a 70 - 72 F250 2wd with 6900,7500 or 8100 GVWR?

robroy's truck is a 8100 or 8200 gvw i think. it is pretty heavy duty from what i remember.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Anyone have a 70 - 72 F250 2wd with 6900,7500 or 8100 GVWR?

Good day Chris!

I have lots of photos of my 1972 F250 Custom 4x2 FE/T18 8,100lb GVW 8' bed truck's front end as it went back together.

To my surprise, I looked and wasn't able to find a FORDification thread wherein I documented the steering arms per se--I think I was fortunate in that they went together without incident, so I wasn't provoked to document them here. I'll run out in the garage this very afternoon and take some good photos for you though!

In the meanwhile, perhaps some of the photos in the following threads will be helpful and/or entertaining.

This thread has some detailed photos of the I-beams, king-pins and spindles: #50's I-beams/spindles 100% and bolted up!

Here you can get a good look at the front part of the frame: RustBullet on #50's frame and I-Beams.

Here you can see more of the spindles and the front disc brakes: #50: 1972 F250 8,100lb GVW Disc Brakes (Tons of Photos)

Chris, I'll update this thread again with photos specifically of the steering arms in under an hour. If you can come up with any measurements that would be helpful for me to take for you, I'd be happy to do that also while I'm out there!

Robroy

I have lots of photos of my 1972 F250 Custom 4x2 FE/T18 8,100lb GVW 8' bed truck's front end as it went back together.

To my surprise, I looked and wasn't able to find a FORDification thread wherein I documented the steering arms per se--I think I was fortunate in that they went together without incident, so I wasn't provoked to document them here. I'll run out in the garage this very afternoon and take some good photos for you though!

In the meanwhile, perhaps some of the photos in the following threads will be helpful and/or entertaining.

This thread has some detailed photos of the I-beams, king-pins and spindles: #50's I-beams/spindles 100% and bolted up!

Here you can get a good look at the front part of the frame: RustBullet on #50's frame and I-Beams.

Here you can see more of the spindles and the front disc brakes: #50: 1972 F250 8,100lb GVW Disc Brakes (Tons of Photos)

Chris, I'll update this thread again with photos specifically of the steering arms in under an hour. If you can come up with any measurements that would be helpful for me to take for you, I'd be happy to do that also while I'm out there!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Anyone have a 70 - 72 F250 2wd with 6900,7500 or 8100 GVWR?

Good afternoon Chris,

I got to searching again and found a thread that shows the longest steering arm! The photo on the top shows my OEM arm and the NAPA replacement side-by-side.

How should the clamps on the drag link sleeve be positioned?

I also found this other thread that has some good photos in it; it might be fun for you to glance through: #50's radius arms and coil springs installed!

I'll run out and take some more steering photos now; stand by for another update soon!

Robroy

I got to searching again and found a thread that shows the longest steering arm! The photo on the top shows my OEM arm and the NAPA replacement side-by-side.

How should the clamps on the drag link sleeve be positioned?

I also found this other thread that has some good photos in it; it might be fun for you to glance through: #50's radius arms and coil springs installed!

I'll run out and take some more steering photos now; stand by for another update soon!

Robroy

-

ChrisB

- New Member

- Posts: 73

- Joined: Thu Jul 28, 2005 6:57 pm

- Location: Southern California

Re: Anyone have a 70 - 72 F250 2wd with 6900,7500 or 8100 GVWR?

Robroy,

I think I see the answer based on your pics. It appears your tie rod end on the left side and on the right side, one side of the drag link bolt to the steering knuckes from the top down. I don't have them in front of me but I'm all but positive my 7500 GVWR 69 Camper Special dual piston caliper front end knuclkes accept the balljoints from the bottom up, the same as my 72 6200 GVWR F250 Custom with 2.0" wide drums.

Your drag link balljoint attached to the pitman comes from the bottom up, as exptected, like both of mine. The drag link having balljoint studs pointing in opposite directions takes care of bolting in to your knuckle from the top down.....the opposite of mine. Why on earth did they change this for one GVWR? Anyone know or have an idea, maybe I'm missing something.

In the pic right above the universal bearing packer tool in the packaging that you posted in one of your threads you can see what I'll call the kingpin locater pin/stud/bolt the purpose of which appears to be keeping the kingpin from moving vertically or rotating. Your hardware appears new. If it is, do you remember or have any paperwork on where it was purchased. Maybe it's widely available but I haven't asked and it hasn't popped up yet. Mine look like parts salvaged from the Titatic, though I'm sure they're still servicable. I'm not taking anything for granted so thought I'd ask since I'd like to use new ones.

On edit, based on the question about the correct orientation of your tie rod ends adjusting sleeve, I believe I read in the original 69 Ford Truck shop manuals I read 1-2 days ago, idleally, the bolts should be towards the front of the vehicle with the nuts towards the ground and the bolt heads towards the sky.

Thanks

Chris

I think I see the answer based on your pics. It appears your tie rod end on the left side and on the right side, one side of the drag link bolt to the steering knuckes from the top down. I don't have them in front of me but I'm all but positive my 7500 GVWR 69 Camper Special dual piston caliper front end knuclkes accept the balljoints from the bottom up, the same as my 72 6200 GVWR F250 Custom with 2.0" wide drums.

Your drag link balljoint attached to the pitman comes from the bottom up, as exptected, like both of mine. The drag link having balljoint studs pointing in opposite directions takes care of bolting in to your knuckle from the top down.....the opposite of mine. Why on earth did they change this for one GVWR? Anyone know or have an idea, maybe I'm missing something.

In the pic right above the universal bearing packer tool in the packaging that you posted in one of your threads you can see what I'll call the kingpin locater pin/stud/bolt the purpose of which appears to be keeping the kingpin from moving vertically or rotating. Your hardware appears new. If it is, do you remember or have any paperwork on where it was purchased. Maybe it's widely available but I haven't asked and it hasn't popped up yet. Mine look like parts salvaged from the Titatic, though I'm sure they're still servicable. I'm not taking anything for granted so thought I'd ask since I'd like to use new ones.

On edit, based on the question about the correct orientation of your tie rod ends adjusting sleeve, I believe I read in the original 69 Ford Truck shop manuals I read 1-2 days ago, idleally, the bolts should be towards the front of the vehicle with the nuts towards the ground and the bolt heads towards the sky.

Thanks

Chris

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Anyone have a 70 - 72 F250 2wd with 6900,7500 or 8100 GVWR?

Good afternoon Chris!

Chris, if you'd like to see that part more closely I could take some photos of my old shabby ones. I think I kept them around for some reason instead of scrapping them, so I could take some photos of those if they'd help you--just let me know if you're interested!

Chris, here are a few photos I just went out there and took. I wish the quality of the photos was better, but I had to use the flash, the my camera's flash doesn't work very well.

Note that you can click directly upon any of these photos to see much larger, higher definition editions.

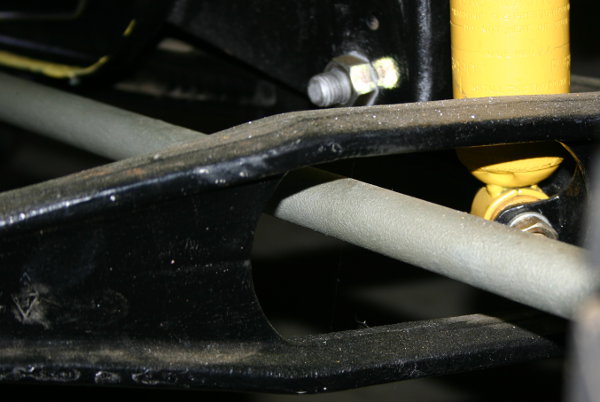

Here's the right (passenger) side steering arm connection at the spindle/knuckle. As you already figured out, it goes in from the top, just like the other side.

Here's the same view zoomed way out, for more visual context.

Here's a wide view of the pitman arm and driver's side areas, to establish a visual context.

And here's a detailed photo of the driver's side connection--it's just like you thought.

Here's a detailed shot of the pitman arm area.

This photo shows how the longest steering arm goes through the radius arm. If you were to buy this heavy GVW steering arm and use it on your 6,200lb GVW truck, I'm not sure if you'd have clearance issues at this spot or not. I'm not able to visualize exactly how your setup would look, but this is a potential trouble-area to consider.

I'll look for my NAPA paperwork on the kingpin kit and let you know shortly!

Robroy

Excellent! I took some more of them that I'll post at the end of my reply; perhaps those will help you to be even more certain about what you're seeing.ChrisB wrote:I think I see the answer based on your pics.

Yes you're right! Both steering arm ends go in to the spindles/knuckles from the top down on the 8,100lb GVW truck.ChrisB wrote:It appears your tie rod end on the left side and on the right side, one side of the drag link bolt to the steering knuckes from the top down.

Interesting!ChrisB wrote:I don't have them in front of me but I'm all but positive my 7500 GVWR 69 Camper Special dual piston caliper front end knuclkes accept the balljoints from the bottom up, the same as my 72 6200 GVWR F250 Custom with 2.0" wide drums.

Indeed!ChrisB wrote:Your drag link balljoint attached to the pitman comes from the bottom up, as exptected, like both of mine.

True!ChrisB wrote:The drag link having balljoint studs pointing in opposite directions takes care of bolting in to your knuckle from the top down.....the opposite of mine.

I'd only be guessing; I have no idea. I've noticed that many of the suspension parts for the 8,100lb GVW F250 seem to be the same parts used on the F350; maybe that's where they switched over.ChrisB wrote:Why on earth did they change this for one GVWR? Anyone know or have an idea, maybe I'm missing something.

Yes you are right--that's exactly what it is! I'm surprised I didn't include any photos of those new parts in my king-pin thread.ChrisB wrote:In the pic right above the universal bearing packer tool in the packaging that you posted in one of your threads you can see what I'll call the kingpin locater pin/stud/bolt the purpose of which appears to be keeping the kingpin from moving vertically or rotating.

Chris, if you'd like to see that part more closely I could take some photos of my old shabby ones. I think I kept them around for some reason instead of scrapping them, so I could take some photos of those if they'd help you--just let me know if you're interested!

Yes it was! It was USA-made hardware that I bought through NAPA. It was a king-pin kit that included new kingpins, kingpin bushings, those bizarre-looking bolts that we're discussing, and the kingpin grease seals (which I've heard of people neglecting to replace, since they're not obvious).ChrisB wrote:Your hardware appears new.

Yes I do have the paperwork, and I'll look up the part number (and the price I paid) for you! It came from NAPA but had to be special-ordered, naturally. I'll look for the info as soon as I'm done with this post and let you know within half an hour or so what I find.ChrisB wrote:If it is, do you remember or have any paperwork on where it was purchased. Maybe it's widely available but I haven't asked and it hasn't popped up yet.

I understand 100%! If you're going to the trouble take that stuff apart, it would naturally be a great idea to use as much new stuff as possible. As long as the new stuff is top quality and USA-made, that is.ChrisB wrote:Mine look like parts salvaged from the Titatic, though I'm sure they're still servicable. I'm not taking anything for granted so thought I'd ask since I'd like to use new ones.

Oh! Well thank you Chris! I'll review the way I set those up in the end to make sure they're in harmony with your suggestion. If they're not, I'll scratch my head about it.ChrisB wrote:On edit, based on the question about the correct orientation of your tie rod ends adjusting sleeve, I believe I read in the original 69 Ford Truck shop manuals I read 1-2 days ago, idleally, the bolts should be towards the front of the vehicle with the nuts towards the ground and the bolt heads towards the sky.

Chris, here are a few photos I just went out there and took. I wish the quality of the photos was better, but I had to use the flash, the my camera's flash doesn't work very well.

Note that you can click directly upon any of these photos to see much larger, higher definition editions.

Here's the right (passenger) side steering arm connection at the spindle/knuckle. As you already figured out, it goes in from the top, just like the other side.

Here's the same view zoomed way out, for more visual context.

Here's a wide view of the pitman arm and driver's side areas, to establish a visual context.

And here's a detailed photo of the driver's side connection--it's just like you thought.

Here's a detailed shot of the pitman arm area.

This photo shows how the longest steering arm goes through the radius arm. If you were to buy this heavy GVW steering arm and use it on your 6,200lb GVW truck, I'm not sure if you'd have clearance issues at this spot or not. I'm not able to visualize exactly how your setup would look, but this is a potential trouble-area to consider.

I'll look for my NAPA paperwork on the kingpin kit and let you know shortly!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Anyone have a 70 - 72 F250 2wd with 6900,7500 or 8100 GVWR?

Good afternoon Chris!

Rather than find my paperwork I went out in the garage and found the box that the kingpin kit came in.

The box has a sticker on it that reads, "NAPA CHASSIS PRECISION ENGINEERED 262-1502," and "Made in USA." Then in very small print, on the bottom of the sticker, it reads, "Supplied to NAPA Distribution Centers by NAPA Chassis, McHenry, IL F03391NAPA."

In the box I discovered my original kingpin bolts (the funny looking ones). These bolts seem to be designed to crush slightly when they're installed and torqued down, since they press up very hard against the side of the kingpin itself. So my original bolts have this crush mark on them already. I think you'd be best off to get brand new ones.

That said, if they'd be of any use to you, or if you need any other small hardware that I might have, I'd be happy to mail it to you.

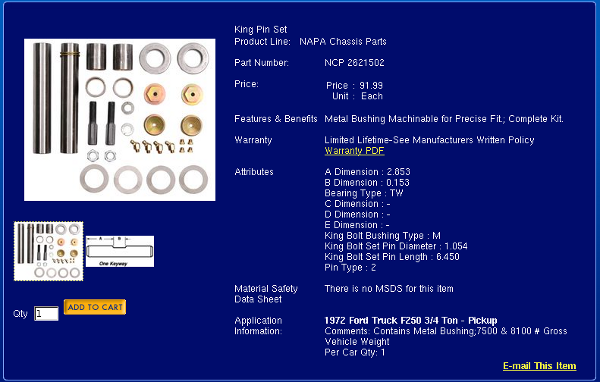

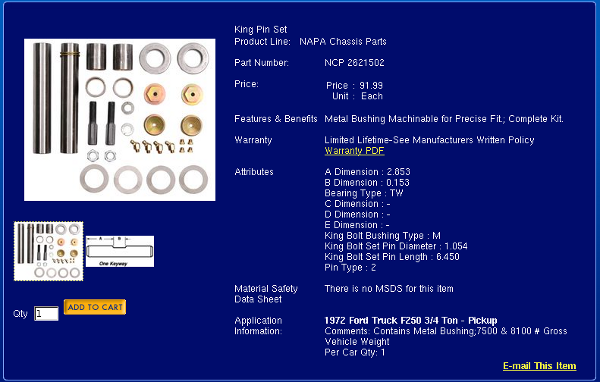

Note that my kit (NAPA 262-1502) is for my kingpin size, which is probably different from the kingpin size on a 6,200lb GVW truck. Here's the online NAPA catalog listing--you'll probably want to click directly upon this image to be able to read it clearly.

It looks like the list price for 262-1502 is $92.

Chris, perhaps using NAPA part 262-1502 as a starting place, you'll be able to find a similar kit that's made for the 6,200lb GVW truck!

One more note: as you probably know, NAPA sells chassis parts in two grades: economy and premium. They seem to have most of the parts for our trucks available in both of those grades. The premium parts are the USA-made parts that you want; the economy parts are typically made in China.

Robroy

Rather than find my paperwork I went out in the garage and found the box that the kingpin kit came in.

The box has a sticker on it that reads, "NAPA CHASSIS PRECISION ENGINEERED 262-1502," and "Made in USA." Then in very small print, on the bottom of the sticker, it reads, "Supplied to NAPA Distribution Centers by NAPA Chassis, McHenry, IL F03391NAPA."

In the box I discovered my original kingpin bolts (the funny looking ones). These bolts seem to be designed to crush slightly when they're installed and torqued down, since they press up very hard against the side of the kingpin itself. So my original bolts have this crush mark on them already. I think you'd be best off to get brand new ones.

That said, if they'd be of any use to you, or if you need any other small hardware that I might have, I'd be happy to mail it to you.

Note that my kit (NAPA 262-1502) is for my kingpin size, which is probably different from the kingpin size on a 6,200lb GVW truck. Here's the online NAPA catalog listing--you'll probably want to click directly upon this image to be able to read it clearly.

It looks like the list price for 262-1502 is $92.

Chris, perhaps using NAPA part 262-1502 as a starting place, you'll be able to find a similar kit that's made for the 6,200lb GVW truck!

One more note: as you probably know, NAPA sells chassis parts in two grades: economy and premium. They seem to have most of the parts for our trucks available in both of those grades. The premium parts are the USA-made parts that you want; the economy parts are typically made in China.

Robroy

-

ChrisB

- New Member

- Posts: 73

- Joined: Thu Jul 28, 2005 6:57 pm

- Location: Southern California

Re: Anyone have a 70 - 72 F250 2wd with 6900,7500 or 8100 GVWR?

Thanks! Looks like the kingpin positioning bolt is included in the LMC kit. At $60 for both with the metal bushing instead of nylon, I'll bet it's Chinese but I'm not going to sweat it at the moment.

I notice the kingpin diameter listed for your kit over 1.000+ is the largest diameter version listed on this site in the disc brake swap 2 page write up. Yours lists two gvwrs for that kingpin. The LMC kit makes no mention of GVWR determination.....so, you bet I'll measure it and report back. My guess is all of the ibeams will accept all diameters, as long as kp diameter and bushing diameter match up correctly? We'll see.

On the over vs under balljoint to steering knuckle, my guess is the steering arm part of the knuckle casting is dropped a bit relative to the spindle stub so the links make it through the radius arm with enough clearance.

I think I'll be in the clear, but have to admit I'm wishing I had a 73-79 donor. In fact 75+ had a slight step up in wheel bearing dimensions as well. My rotor will be 1.0 wide new which is a bit narrow for heavy work. the newer disc 75+ IIRC is 1.25 wide and the same ~ 12.5" diameter which should be adequate. As long as materials are OK and the thing isn't really abused, I should be warpage free.

I'll post some pics as the install comes together....and of course I'll ask more questions if they come up.

That 406 FE motor looks like it's built for some fun. I've never owned an FE motor till I bought the 69 donor for this project. It has a 390 that seems basically sound though it has some issues, I think are striclty carburation and ignition related in that order...I'm trying to decide what to do with the donor. I feel like building a low buck truck 'rod' out of it for some light work and fun....

Thanks

Chris

I notice the kingpin diameter listed for your kit over 1.000+ is the largest diameter version listed on this site in the disc brake swap 2 page write up. Yours lists two gvwrs for that kingpin. The LMC kit makes no mention of GVWR determination.....so, you bet I'll measure it and report back. My guess is all of the ibeams will accept all diameters, as long as kp diameter and bushing diameter match up correctly? We'll see.

On the over vs under balljoint to steering knuckle, my guess is the steering arm part of the knuckle casting is dropped a bit relative to the spindle stub so the links make it through the radius arm with enough clearance.

I think I'll be in the clear, but have to admit I'm wishing I had a 73-79 donor. In fact 75+ had a slight step up in wheel bearing dimensions as well. My rotor will be 1.0 wide new which is a bit narrow for heavy work. the newer disc 75+ IIRC is 1.25 wide and the same ~ 12.5" diameter which should be adequate. As long as materials are OK and the thing isn't really abused, I should be warpage free.

I'll post some pics as the install comes together....and of course I'll ask more questions if they come up.

That 406 FE motor looks like it's built for some fun. I've never owned an FE motor till I bought the 69 donor for this project. It has a 390 that seems basically sound though it has some issues, I think are striclty carburation and ignition related in that order...I'm trying to decide what to do with the donor. I feel like building a low buck truck 'rod' out of it for some light work and fun....

Thanks

Chris