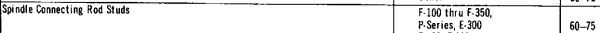

Today I applied the shop manual's torque spec to the spindle connecting rod studs, like this one:

I set my torque wrench to about 67 ft/lbs based on this line from the 1972 Ford Truck Shop Manual, 16-01-09,

After torquing them, I wanted to put the cotter pins in. But naturally the holes in the studs for the pins didn't line up with the grooves in the castle nuts!

I figured I'd just back it off one notch. But when I backed it off, it basically lost ALL of its torque--it was only finger tight then! Then I figured I'd just tighten it down until I hit the next notch. But this stepped the torque way up to something around 85 ft/lbs. It seems like a lot of torquing action happens in a very small amount of space with those studs and nuts!

So which is better: the nut on there only finger tight, or the nut on there a little over the factory torque spec? I'm guessing the latter, but I'm not sure how tight these are really supposed to be.

Thanks very much!

Robroy