Welding question

Moderator: FORDification

- wt4speed#2

- Blue Oval Guru

- Posts: 1064

- Joined: Fri Mar 25, 2005 9:21 pm

- Location: Texas, Ft. Worth

Welding question

I have procured some thin square tubing that i think will be a good start on my new radiator mounting system(long story maybe later). the only draw back it's galvanized. What are some of the pro's and cons for welding galvanized sheet metal? will i be okay if i keep good ventilation?

- OldRedFord

- Blue Oval Guru

- Posts: 1314

- Joined: Tue Jan 29, 2008 11:37 pm

- Location: Hull GA

- Contact:

re: Welding question

I wouldn't do it.

Im in college to be a welder and I wont touch it.

But if you must..

Another link worth reading...

http://www.anvilfire.com/iForge/tutor/safety3/index.htm

Im in college to be a welder and I wont touch it.

But if you must..

But I still wouldn't do it. Still a chance of getting Metal Fume Fever.Welding galvanized steel should always be done in well-ventilated locations to minimize fume inhalation. The AWS publication, AWS/ANSI Z49:1, Safety and Cutting in Welding, covers all aspects of welding safety and health. However, galvanized steel can be welded without removing the zinc coating if special procedures are followed.

For galvanized structural fabrications, the zinc coating should be removed at least one to four inches from either side of the intended weld zone and on both sides of the piece. Grinding back the zinc coating is the preferred and most common method; burning the zinc away or pushing back the molten zinc from the weld area also are effective.

Another link worth reading...

http://www.anvilfire.com/iForge/tutor/safety3/index.htm

Tim

1972 F350 flatbed drw c6/390

1967 F600 project truck

1972 F350 flatbed drw c6/390

1967 F600 project truck

- ezernut9mm

- 100% FORDified!

- Posts: 2803

- Joined: Sun Nov 26, 2006 5:25 pm

- Location: Missouri, Kansas City

-

mark carrick

- New Member

- Posts: 13

- Joined: Sat Apr 19, 2008 11:27 am

- Location: Chula Vista

You'll be fine, grind the zinc to bare metal in the area to be welded (there will be far less oxdation and popping/pitting) turn on a fan and try to avoid breathing alot of smoke. A little shouldn't hurt. I've been a sheet metal mechanic for over fifteen years and have welded an awful lot of galvanized duct, and I'm not dead yet.

"Give a man afish and he will eat for a day; teach a man to fish and he will sit in a boat and drink beer all day." Author unknown.

- 19674x4

- Blue Oval Fanatic

- Posts: 903

- Joined: Mon Jun 27, 2005 12:31 am

- Location: Oakland Oregon/Sheridan Wyoming

yea, just grind the galvanizing off and go from there. not only is it safer, but makes the weld penetrate better and create a better bond

My Photo Album

2012 Cummins-the luxury Tow Pig

1967 F-250 highboy 352, np435(((((((sold))))))))) My first true love

1968 F100 SWB. 360, np-435, flatbed, currently acting as a hornest nest and bee hive.

1971 F-100 4x4 Step-side. 360, np-435, 70k origional miles- needs allot of love.

2012 Cummins-the luxury Tow Pig

1967 F-250 highboy 352, np435(((((((sold))))))))) My first true love

1968 F100 SWB. 360, np-435, flatbed, currently acting as a hornest nest and bee hive.

1971 F-100 4x4 Step-side. 360, np-435, 70k origional miles- needs allot of love.

- 71Ford100

- Preferred User

- Posts: 281

- Joined: Sat Oct 02, 2004 6:03 pm

- Location: Wyoming, Burns

re: Welding question

Also drink some milk before you go and tear into it. I welded on galvanized beams all summer long with no problem.

Lance Peters

'72 250 4x4 project,''71 F-100 daily driver,69 F-250 4x4 Crew, '68 F-100, '68 F-250 crew under restoration, '52 Dodge 1/2 ton overload, gazillion tractors and combines

'72 250 4x4 project,''71 F-100 daily driver,69 F-250 4x4 Crew, '68 F-100, '68 F-250 crew under restoration, '52 Dodge 1/2 ton overload, gazillion tractors and combines

- rjewkes

- 100% FORDified!

- Posts: 3711

- Joined: Sun Apr 17, 2005 1:09 am

- Location: Missouri, Webb City

- Contact:

is this replacing the original core support completley or making a stand off for the rad? is this to make room for the a/c condensor?

my current 302 f100 has the rad bolted directly to the xcore support it is a 72 though so if yours is older maybe?

my current 302 f100 has the rad bolted directly to the xcore support it is a 72 though so if yours is older maybe?

"It is better to keep your mouth shut and appear stupid than to open it and remove all doubt." - Mark Twain

'70 f250 4x4 Crew cab 460/C6 '72 F100 390/C6 9.8 MPG AVG. '89 Mercury Cougar LS Dual Exh. V6 . 18.9 MPG AVG. In Town.

I don't want to give em a heart-attack. That is what would happen if I answered the door in the buff. Heck it almost scares me to death when I step out of the shower and look in the mirror.~Mancar1~

fuelly.com

'70 f250 4x4 Crew cab 460/C6 '72 F100 390/C6 9.8 MPG AVG. '89 Mercury Cougar LS Dual Exh. V6 . 18.9 MPG AVG. In Town.

I don't want to give em a heart-attack. That is what would happen if I answered the door in the buff. Heck it almost scares me to death when I step out of the shower and look in the mirror.~Mancar1~

fuelly.com

- wt4speed#2

- Blue Oval Guru

- Posts: 1064

- Joined: Fri Mar 25, 2005 9:21 pm

- Location: Texas, Ft. Worth

- 67mann

- 100% FORDified!

- Posts: 1705

- Joined: Thu Feb 07, 2008 7:19 am

- Location: NY..Mt.Morris 3rdgen. homestead

re: Welding question

LOT's of ventilation and you'll be fine,you can drink milk too--if ya want,but it doesn't sound like your makin a career out of welding galvinize

Just a little project.

Just a little project.

I've had enough and I'm not alone

http://s267.photobucket.com/albums/ii304/67mann/

http://s267.photobucket.com/albums/ii304/67mann/

- wt4speed#2

- Blue Oval Guru

- Posts: 1064

- Joined: Fri Mar 25, 2005 9:21 pm

- Location: Texas, Ft. Worth

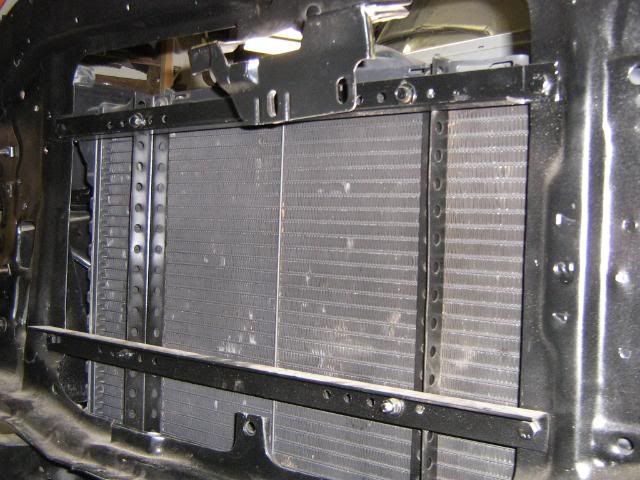

I used the radiator that I got along with the 302 roller as it was the lesser of the 2 evils . The radiator that was in the truck when I purchased it was clearly not the right application as the PO had to cut out the stantions or uprights if you will, one of the reasons I replaced the core support. it was secured to the core support with pallet banding materials. I fabricated makeshift brackets to install the '85 stang radiator with plans to redesign it at a later time (see photo's)rjewkes wrote:is this replacing the original core support completley or making a stand off for the rad? is this to make room for the a/c condensor?

my current 302 f100 has the rad bolted directly to the xcore support it is a 72 though so if yours is older maybe?

In the processes of tuning the new carb installed on the Offy dual plane (thanks willow) fitswell and I discovered the 'stang radiator was plugged or something . So thur the course of several months (ovedrtime cuts , chrstmas and the likes) I finally came up with funds to reoplace the rad. and decioded since I have the 'stang style nearly installed that's what I would buy. long and short the vendor i used screwed up and sent me a new"zella" simular to this

and I dont really want to bolt it directly like the copper and brass that's currently in there. I plan on building a troff<spelling> for it to sit in, in rubber mounts and fill the open portion at the top with clamp brackets and rubber. I know i've lost some here but will try to take picture as i go when i get my core support off and start fabricating.

- wt4speed#2

- Blue Oval Guru

- Posts: 1064

- Joined: Fri Mar 25, 2005 9:21 pm

- Location: Texas, Ft. Worth

- fourtss

- New Member

- Posts: 183

- Joined: Tue Mar 21, 2006 3:16 pm

- Location: Missouri, Edina

- Contact:

re: Welding question

tony, are you doin this cause you don't have the correct radiator?

tom

2003 ford escape

1997 dodge 1500 4wd 5speed, 1963 Cheby Corvair,

2003 ford escape

1997 dodge 1500 4wd 5speed, 1963 Cheby Corvair,

- wt4speed#2

- Blue Oval Guru

- Posts: 1064

- Joined: Fri Mar 25, 2005 9:21 pm

- Location: Texas, Ft. Worth

yes the PO had rigged a radiator from God knows what. And I had and whatI thought was a decent Mustang rad, with shroud and recovery bottle and fab it up to go in the support. when I discovered that it was blocked I was just gonna go like for like as the mounting was 80% done. Long and shoet I ended up with a High dollar alminunm radiator that can't just be bolted up direct.