Hey Jamie, thanks for replying!

I'll have to sit with a piece of rope and try to work through your instructions--that sounds like you know of a good method! I like the idea of the arrangement providing a 3-1 assist to making the line tight.

You're on a confined space rescue team? Wow! What's your industry (I remember seeing a panoramic photo of some huge machine you were working on once, but didn't know what it was)?

Well on to the full report of my visit to FE Specialties!

I got there at 2:00PM and Tom checked out the engine, showed me around his shop, and showed me his very impressive Mustang until 4:30PM! Tom is obviously a quality oriented guy who really knows how to treat customers. I know he had a lot of engines and cars going on around there, but during my visit he wanted to do everything he could to make it as fun as possible--he wasn't in a rush with me! If only I could remember and fully understand all the interesting things he mentioned.

I got the distinct impression that he's interested in building quality engines, and not trying to "sell" me anything. In fact, it almost seemed like visiting a buddy who happened to be an FE engine expert! Zero pressure, zero rush. What a quality guy huh?

Here are some additional observations Tom made about the engine (I'm sure I've forgotten some important ones, but here goes):

- He couldn't see any porting work on the heads (by looking in the exhaust ports with a flashlight), so they seem stock.

- He noted that the RTV used with the intake manifold was beginning to shrink away from the mating surfaces in one spot. He mentioned that RTV tends to do that, which is why he rarely uses it.

- He observed that several of my spark plugs had lots of oil on them. I told him about how I'd put oil directly in to the cylinders and turned the engine over, and he advised me to only use WD-40 in the future. He explained that it's possible for oil to become trapped between the two compression rings. Then when the engine's fired over, the oil can actually burn inside there, where it's trapped! And that can cause some nasty deposits in the area, which are bad for the engine. He stressed how important cleanliness is to an engine.

- He noted that my D3TE engine block was the "Mirror block," or the "Mirror 105 block," (I forget which), and that it's a desirable block. The Steve Christ book also mentions that this is a good block (because of various reinforcements in casting, as I remember).

- He noted that my after market distributor hold-down clip was pressing down only on one edge of the distributor, and he might want to swap it out with a factory hold-down (which presses more evenly on the top of the distributor).

- I offered my fouled oil filter element to him in case he wanted to check it out, and he said he definitely did! He might cut it open to see how much metal is in there, just to satisfy curiosity.

- I showed him the Milodon windage tray that caused so much trouble, and he found that quite interesting. He held on to it to experiment to see exactly what it was hitting on the crank. Tom seemed genuinely curious about the engine!

- I mentioned the trouble I'd had in getting the block to retain the dipstick tube (it seemed like a semi-loose fit). Tom mentioned that it's made that way on purpose, because they didn't want people to tap the tube in to the block, possibly causing metal shavings to fall down in the oil pan! He said that he usually uses a type of clear adhesive on that area. He added that the RTV I'd used there wasn't a good idea, because RTV tends to shrink away from the mating surfaces, leaving passages for fluid to leak through.

Unlike most shops I've hired, Tom welcomed as many photos as I'd like to take. In fact, he even agreed to a video-recorded interview about the engine (and any modifications he did to it) when I come to pick it up! He is proud of his work!!!

Click on the photos for full resolution editions.

Here's Tom's engine building room. It was very clean and organized looking! The engine in the middle is a 390 that he's building for another customer. Looks pretty immaculate huh?

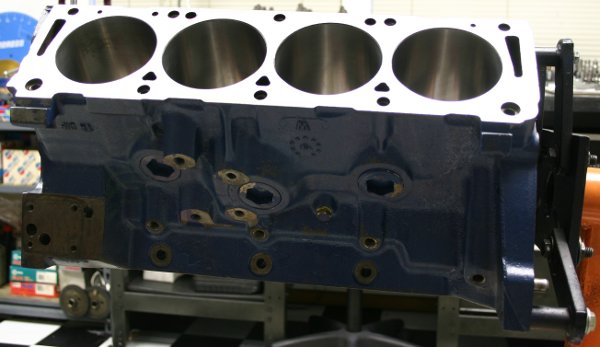

Here are some detailed photos of this super clean looking 390 block. The customer he's building this for was actually there when I arrived, talking with Tom in the engine room.

Tom's storage area of FE goods!

This 427 block is one of Tom's own projects.

Tom mentioned that this patch was done back in the 1970's. If I remember correct, Tom guessed that this engine "lost a rod!"

Here's another 427 Tom's working on. This one is a factory block from a Shelby Cobra that's going in to a customer's car (I think I saw the Cobra in his garage/shop area).

I heard from Tom that this block is super original--note that there are no tapped threads in the raised surfaces around the camshaft plug.

Tom also mentioned that this casting number, C5AE-H, shows that it's a desirable block!

Tom showed me his amazing Mustang! Before yesterday I'd never seen a car anything like this before. It sounded insanely aggressive and loud (in a good way). Even while standing four or five feet from the car I could feel the sound waves hitting my body! And when he revved the engine once, it caused a roll of teflon tape to JUMP on his nearby workbench--I'm pretty sure the sound waves caused it to jump (really)!

EDIT: Upon looking at the video clip of this engine run, it actually appears that the tape fell down from a shelf on his workbench; it didn't jump in the air spontaneously as I previously thought!

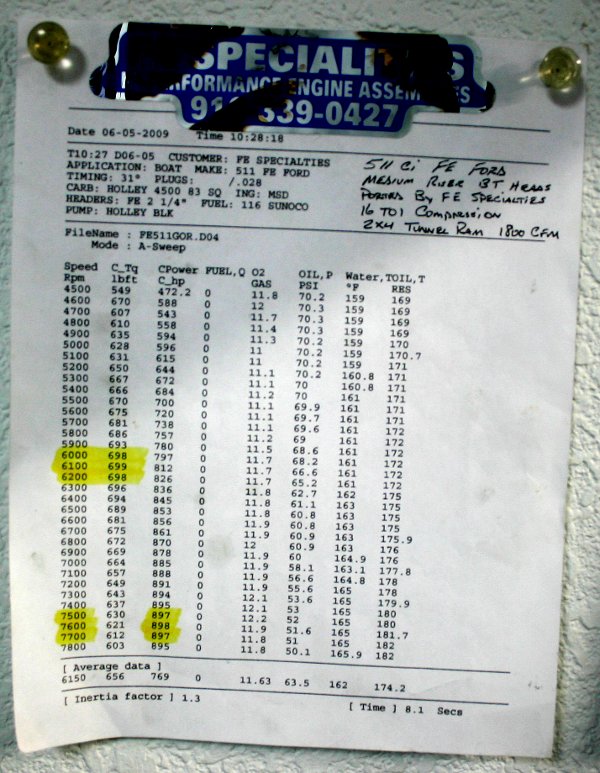

And here's a dyno output sheet for an FE Tom built (not the one that's in his Mustang). Tom noted that even for the dyno runs, he leaves the air/fuel ratio at a level safe for continued operation. In other words, he doesn't doctor up the engine in an unstable way to get the highest dyno rating possible--he prides himself on this point! He had a wall with a bunch of these printouts pinned to it from the various engines he built!

And here's the one photo I took during the drive back. It was quite a drive--you get the idea!

Robert, thanks again for letting me know about FE Specialties. It's fantastic that I have the opportunity to have the engine re-done by Tom--this guy is the best!!!

Robroy