Is it feasible to construct a temporary exhaust system?

Moderators: Ranchero50, DuckRyder

- DuckRyder

- Moderator

- Posts: 4928

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: Is it feasible to construct a temporary exhaust system?

1, 2, 3 I have little experience with ball sockets at least of this type... but I would think you could get enough out of it to work temporarily. I would not tighten it any more than required to keep it from falling off, even if they are to deform, you do not want them to for a temporary system. Yes, they are installed correctly.

4, 2.5 mufflers are designed to slip over 2.5 pipes. You can probably get 2.5 pipe in short sections with a slip fit on one end so that you can extend the collectors them attach pipe at one of the local big box stores. Again, I would only tighten clamps tight enough to keep it from falling off.

4, 2.5 mufflers are designed to slip over 2.5 pipes. You can probably get 2.5 pipe in short sections with a slip fit on one end so that you can extend the collectors them attach pipe at one of the local big box stores. Again, I would only tighten clamps tight enough to keep it from falling off.

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Is it feasible to construct a temporary exhaust system?

Hey Robert thanks very much for replying!

I understand what you're saying about not wanting to deform the pipes for a temporary system--it's just like not wanting to crush a copper crush washer until it's being installed for the final time (I guess)!

Thanks again for your five star reply Robert!

Robroy

OK! So if I don't tighten them down a ways beyond the stage when they're just on well enough not to fall off, there will be some visible cracks between the headers (the ball part) and the couplings (the socket part). Do you think that'll make a huge racket with exhaust blasting out of those cracks? I'm not sure how exhaust systems behave under those conditions.DuckRyder wrote: I have little experience with ball sockets at least of this type... but I would think you could get enough out of it to work temporarily. I would not tighten it any more than required to keep it from falling off, even if they are to deform, you do not want them to for a temporary system. Yes, they are installed correctly.

I understand what you're saying about not wanting to deform the pipes for a temporary system--it's just like not wanting to crush a copper crush washer until it's being installed for the final time (I guess)!

OK, thanks! I don't completely understand what's meant by attaching pipe at a local big box store. Do you mean that I can find 2.5" pipe in short sections at those stores?4, 2.5 mufflers are designed to slip over 2.5 pipes. You can probably get 2.5 pipe in short sections with a slip fit on one end so that you can extend the collectors them attach pipe at one of the local big box stores. Again, I would only tighten clamps tight enough to keep it from falling off.

Thanks again for your five star reply Robert!

Robroy

- rjewkes

- 100% FORDified!

- Posts: 3711

- Joined: Sun Apr 17, 2005 1:09 am

- Location: Missouri, Webb City

- Contact:

Re: Is it feasible to construct a temporary exhaust system?

Yup exactly get the 2.5" outer diameter pipe that at one end will have a step up to 2.5 inner to go over your extender. it will leak a bit but won't sound as bad as open headers to the neighbors.

"It is better to keep your mouth shut and appear stupid than to open it and remove all doubt." - Mark Twain

'70 f250 4x4 Crew cab 460/C6 '72 F100 390/C6 9.8 MPG AVG. '89 Mercury Cougar LS Dual Exh. V6 . 18.9 MPG AVG. In Town.

I don't want to give em a heart-attack. That is what would happen if I answered the door in the buff. Heck it almost scares me to death when I step out of the shower and look in the mirror.~Mancar1~

fuelly.com

'70 f250 4x4 Crew cab 460/C6 '72 F100 390/C6 9.8 MPG AVG. '89 Mercury Cougar LS Dual Exh. V6 . 18.9 MPG AVG. In Town.

I don't want to give em a heart-attack. That is what would happen if I answered the door in the buff. Heck it almost scares me to death when I step out of the shower and look in the mirror.~Mancar1~

fuelly.com

- DuckRyder

- Moderator

- Posts: 4928

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: Is it feasible to construct a temporary exhaust system?

Exactly. By "box store" I mean Autozone/Advance/O'Reilly/Kragen/and so forth and so on.

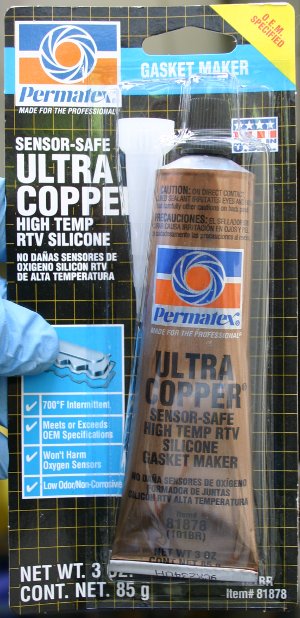

You can also use hi tempature copper RTV to help seal it vs tight clamping. The clamps will deform the pipes and you don't want to do that if you are reusing the mufflers or reducers/ball joints.

Walker also makes stainless band clamps, they are expensive though but won't deform the pipes as badley.

http://www.summitracing.com/parts/WLK-33226/

NAPA sometimes has these although I've never looked for 2.5 at NAPA.

You can also use hi tempature copper RTV to help seal it vs tight clamping. The clamps will deform the pipes and you don't want to do that if you are reusing the mufflers or reducers/ball joints.

Walker also makes stainless band clamps, they are expensive though but won't deform the pipes as badley.

http://www.summitracing.com/parts/WLK-33226/

NAPA sometimes has these although I've never looked for 2.5 at NAPA.

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: Is it feasible to construct a temporary exhaust system?

If you end up with a set of offset inlet / outlet mufflers you can just tech screw them on to the header collectors for temporary exhaust. Ball socket stuff is great. Some high temp RTV and tighten the bolts up decent and it'll be good to go.

Jamie

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Is it feasible to construct a temporary exhaust system?

Hey Jamie thanks for replying!

So that could work!

I'm not familiar with tech screws--are these the guys you're referencing?

Also, don't you think it would be a bad idea to put holes in the muffler inlets and collectors? Or are those patched in a fraction of a second during the welding job to do the final exhaust?

Thanks very much Jamie!

Robroy

OK, thanks! The mufflers I've ordered are Borla Turbo XLs, which do indeed have an offset. Here they are:Ranchero50 wrote:If you end up with a set of offset inlet / outlet mufflers you can just tech screw them on to the header collectors for temporary exhaust.

So that could work!

I'm not familiar with tech screws--are these the guys you're referencing?

Also, don't you think it would be a bad idea to put holes in the muffler inlets and collectors? Or are those patched in a fraction of a second during the welding job to do the final exhaust?

OK, thanks! I'll definitely get some of that high temperature, copper RTV stuff. I've never used that before. Do I just smear a bunch of it around the outside of the seam, once the ball and socket components are coupled? And when I'm ready to take it apart, how easily does that RTV come off?Ranchero50 wrote:Ball socket stuff is great. Some high temp RTV and tighten the bolts up decent and it'll be good to go.

Thanks very much Jamie!

Robroy

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: Is it feasible to construct a temporary exhaust system?

If the Borla's are true stainless you'll need some decent drill bits for the tech screws. The RTV just smear a 1/4" bead on the female part of the ball before putting it together. A little wiggle and the RTV will come right off.

Jamie

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- DuckRyder

- Moderator

- Posts: 4928

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: Is it feasible to construct a temporary exhaust system?

I personally wouldn't screw them, particularly if the borlas actualy have that slot in the inlet... that will allow the joint to grip more easily without actually deforming.

It is hard to tell from your picture, but if those collectors end where mine do (very close to and over the suspension cross memeber) I don't see how you are going to be able to attach the mufflers directly to the reducer/collector.

Also, keep in mind that if you plan to raise the RPM the shorter the pipe, the lower in the RPM range it is going to get VERY loud.

It is hard to tell from your picture, but if those collectors end where mine do (very close to and over the suspension cross memeber) I don't see how you are going to be able to attach the mufflers directly to the reducer/collector.

Also, keep in mind that if you plan to raise the RPM the shorter the pipe, the lower in the RPM range it is going to get VERY loud.

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Is it feasible to construct a temporary exhaust system?

Hi Jamie and Robert thanks very much for the replies!

So I'm hoping to run a very short section of pipe from the collector area back a ways, until there's an area with room for the mufflers. Hopefully that'll work out!

I'm guessing that loudness if all relative so even with a short pipe run and the Borlas, it'll be super quiet compared to using the open headers! I'll be certain to at least have ear plugs in the first time I fire it up. Maybe both ear plugs and muffs.

Thanks very much for all your great advice Jamie and Robert!!!

Robroy

OK thanks for the warning! If I choose to drill 'em I'll remember this tip.Ranchero50 wrote:If the Borla's are true stainless you'll need some decent drill bits for the tech screws.

Got it, thank you! This I'll do.Ranchero50 wrote:The RTV just smear a 1/4" bead on the female part of the ball before putting it together. A little wiggle and the RTV will come right off.

Yeah, I'm going to try it without screwing them first. Although it may hold them better, I'm shy about running screws through such fancy mufflers for a temporary setup.DuckRyder wrote:I personally wouldn't screw them, particularly if the borlas actualy have that slot in the inlet... that will allow the joint to grip more easily without actually deforming.

Yes, my headers end right over that crossmember too! They're actually slightly towards the engine area from the crossmember, but certainly above it. And I think you're right--there's no way I'll be able to attach the Borlas directly to those pipes there. There wouldn't be any room for sure.DuckRyder wrote:It is hard to tell from your picture, but if those collectors end where mine do (very close to and over the suspension cross memeber) I don't see how you are going to be able to attach the mufflers directly to the reducer/collector.

So I'm hoping to run a very short section of pipe from the collector area back a ways, until there's an area with room for the mufflers. Hopefully that'll work out!

OK, thanks! I had no idea. I guess I would have found out the hard way!DuckRyder wrote:Also, keep in mind that if you plan to raise the RPM the shorter the pipe, the lower in the RPM range it is going to get VERY loud.

I'm guessing that loudness if all relative so even with a short pipe run and the Borlas, it'll be super quiet compared to using the open headers! I'll be certain to at least have ear plugs in the first time I fire it up. Maybe both ear plugs and muffs.

Thanks very much for all your great advice Jamie and Robert!!!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Is it feasible to construct a temporary exhaust system?

I ordered some flexible, stainless, 2.5" tubing from Summit to connect the mufflers to the headers. Hopefully it will hold up for long enough to tinker around with the engine and drive it to get its "real" exhaust!

And the Borla Turbo XL mufflers also arrived.

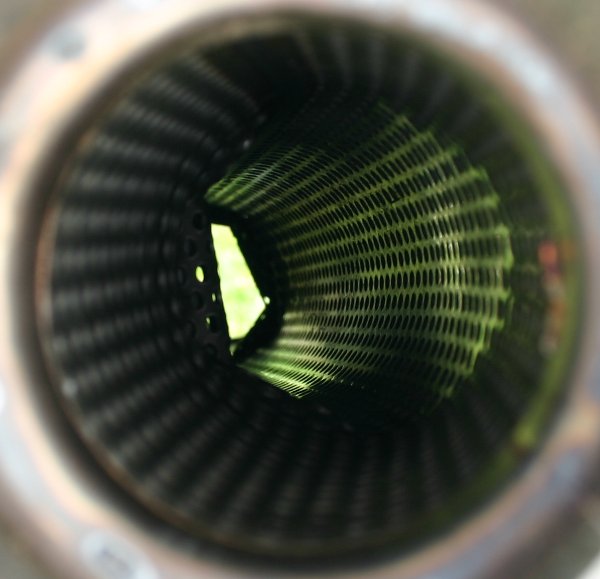

These are obviously flow-through mufflers; you can see right through them!

I wanted to hang the mufflers in the zone occupied by the front driveshaft half, so I installed some temporary brackets in the frame to provide something to hang them from. These brackets seem to have been designed for concrete work but they work for this just fine.

As advised, here's the stuff I used to try to seal up the cracks.

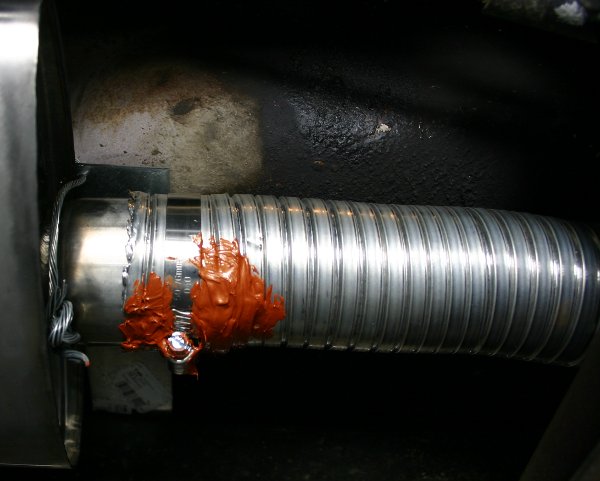

And here's my not-so-fancy, temporary exhaust system! I know it's really funky to hang mufflers with bits of wire but it seems secure enough for garage testing and a few drives. Actually I can pull down pretty hard on the mufflers and shake 'em all around and they don't come loose, although they're free to wobble around a bunch.

And here's the part I'm least proud of. The flexible tubing just wouldn't slip over the mufflers, so I had to cut a slice up the side of the tubing and just jam it on there. Then I patched the crack with a bunch of RTV! This is a major hack, but hopefully it'll last long enough to do some garage testing and make it to the exhaust shop.

The section of tubing on the driver's side. The passenger's side looks similar.

Unlike the funky connections at the mufflers, the tubing slipped over the header collectors very nicely! I got a good seal there, I think.

Another shot of the driver's side muffler with its lame connection to the stainless tubing. The rear side of the mufflers is supported by two independent pieces of wire, and the front is supported by a piece of wire (attached to the funny brackets I installed) and the flexible exhaust tubing itself. It feels surprisingly sturdy when I grab it and shake it around, but I'm not really proud of how this turned out. I'll be happy when it's a funny memory and the real exhaust tubing has been welded in!

I had an extra length of the tubing that I hacked up like Freddy Kruger to remove; it seemed easier than drilling a hole for my tin snips to get their initial bite in. Can you tell that I skipped Metal Shop in Junior High School?

The passenger side tubing attached to the header, viewed from above.

So despite the obvious, significant shortcomings of this setup, do ya'll think it'll be a big improvement over open headers for some in-garage testing and a drive to the muffler shop?

The first time I start the engine, I'll find out! Maybe the whole thing will come unceremoniously unglued with a sound like the Tin Man being tackled by a hundred football quarterbacks.

The good part is that I managed to avoid messing up the headers and mufflers with my funky setup. The mufflers shop shouldn't have any problems building a real exhaust system with them (I think).

Thanks very much for the great advice!

Robroy

And the Borla Turbo XL mufflers also arrived.

These are obviously flow-through mufflers; you can see right through them!

I wanted to hang the mufflers in the zone occupied by the front driveshaft half, so I installed some temporary brackets in the frame to provide something to hang them from. These brackets seem to have been designed for concrete work but they work for this just fine.

As advised, here's the stuff I used to try to seal up the cracks.

And here's my not-so-fancy, temporary exhaust system! I know it's really funky to hang mufflers with bits of wire but it seems secure enough for garage testing and a few drives. Actually I can pull down pretty hard on the mufflers and shake 'em all around and they don't come loose, although they're free to wobble around a bunch.

And here's the part I'm least proud of. The flexible tubing just wouldn't slip over the mufflers, so I had to cut a slice up the side of the tubing and just jam it on there. Then I patched the crack with a bunch of RTV! This is a major hack, but hopefully it'll last long enough to do some garage testing and make it to the exhaust shop.

The section of tubing on the driver's side. The passenger's side looks similar.

Unlike the funky connections at the mufflers, the tubing slipped over the header collectors very nicely! I got a good seal there, I think.

Another shot of the driver's side muffler with its lame connection to the stainless tubing. The rear side of the mufflers is supported by two independent pieces of wire, and the front is supported by a piece of wire (attached to the funny brackets I installed) and the flexible exhaust tubing itself. It feels surprisingly sturdy when I grab it and shake it around, but I'm not really proud of how this turned out. I'll be happy when it's a funny memory and the real exhaust tubing has been welded in!

I had an extra length of the tubing that I hacked up like Freddy Kruger to remove; it seemed easier than drilling a hole for my tin snips to get their initial bite in. Can you tell that I skipped Metal Shop in Junior High School?

The passenger side tubing attached to the header, viewed from above.

So despite the obvious, significant shortcomings of this setup, do ya'll think it'll be a big improvement over open headers for some in-garage testing and a drive to the muffler shop?

The first time I start the engine, I'll find out! Maybe the whole thing will come unceremoniously unglued with a sound like the Tin Man being tackled by a hundred football quarterbacks.

The good part is that I managed to avoid messing up the headers and mufflers with my funky setup. The mufflers shop shouldn't have any problems building a real exhaust system with them (I think).

Thanks very much for the great advice!

Robroy

- DuckRyder

- Moderator

- Posts: 4928

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: Is it feasible to construct a temporary exhaust system?

That should quiten it down a good deal. (IE: it should acomplish what you want it to)

I would keep an eye on the cable where it contacts the pipes an mufflers, don't want the vibration turning it into a saw.

I'd try to clean the copper RTV off of the headers before cranking (on the flange and collector) as it could stain if not.

I would keep an eye on the cable where it contacts the pipes an mufflers, don't want the vibration turning it into a saw.

I'd try to clean the copper RTV off of the headers before cranking (on the flange and collector) as it could stain if not.

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Is it feasible to construct a temporary exhaust system?

Good morning Robert, thanks for replying!

Thanks again Robert!

Robroy

Excellent, thanks Robert!DuckRyder wrote:That should quiten it down a good deal. (IE: it should acomplish what you want it to)

I know just what you mean. I'll climb under there and inspect it very carefully after each run. And I'll probably only run it maybe five times before taking the drive to the muffler shop. At least just from my observations while hanging them up, the skin on the mufflers seems very durable. But I'll be super careful about this!DuckRyder wrote:I would keep an eye on the cable where it contacts the pipes an mufflers, don't want the vibration turning it into a saw.

OK, thanks for pointing this out! I remember reading in the manual for the headers that they should be ultra clean the first time they're run, for the very reason you're mentioning. I'll clean them up as well as I'm able to!DuckRyder wrote:I'd try to clean the copper RTV off of the headers before cranking (on the flange and collector) as it could stain if not.

Thanks again Robert!

Robroy