FE and T18/C6 mounts from Autofab, plus frame alignment.

Moderators: Ranchero50, DuckRyder

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: FE motor and trans' mounts from Autofab; alignment problem!

Ok, It's hard to describe machine driveline alignment / vibration analysis in laymans terms. I'm not real good at it myself and we do it at work all the time. Think about your exhaust system as the truck is running in nuetral. If you run an X pipe vs and H pipe at certain RPMs the tone changes from rumbly to smooth and back. Vibration analysis is kind of like that. You listen to one point in the driveline and look at the noise spectrum at that point. You can literally see bearing noise, but not just bearing noise, you can see if the inner race is loose on the shaft, if the balls are pitted, if the cage is loose and even if the outer race is loose in the bearing box. Alignment is the difference in angularity and offset between two shafts (think mainshaft on the tranny and pinion on the differential). Now it you go from shaft to shaft the U joints compensate for alignment issues. If the angle or offset are too much it will vibrate at certain frequency (RPM) and load.

Now for truck driveline stuff if you have a looseness in the driveline or a spot not loaded correctly (looose or overloaded) or an imbalance condition it will vibrate. Do a search on setting pinion angle for some better understanding of U joint angles and how they effect each other.

Jamie

Now for truck driveline stuff if you have a looseness in the driveline or a spot not loaded correctly (looose or overloaded) or an imbalance condition it will vibrate. Do a search on setting pinion angle for some better understanding of U joint angles and how they effect each other.

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

Hey Jamie that's interesting. So in your shop, you can record driveline vibration and see it graphed on a screen?

I'll search as you've suggested and see what I can learn.

Thanks again,

Robroy

I'll search as you've suggested and see what I can learn.

Thanks again,

Robroy

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

We actually have a subdepartment that looks for problems. I fix them...

One of my babies,

Jamie

One of my babies,

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

Hey Jamie, that looks "bad to the bone."

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

Over the past few days I've been following Jamie's alignment advice. I got the motor mount to frame bolts loose and was amazed at how easily I could move the engine+transmission around that way! And using Jamie's method it was easy to achieve whatever alignment I wanted, which was fantastic. I haven't tightened up the bolts yet to see if my work will "stick," but at least the results are great so far.

One issue that remains is that the entire engine+transmission seem to be located about 1/4" or 1/2" further back than they used to be. At first I thought it was just my fancy Autofab transmission mount, but I compared it to the factory mount and the engine+transmission really are 1/4" to 1/2" closer to the rear of the truck than they used to be.

I can't see any way to shift the entire motor and transmission forward 1/4" or 1/2" without making slots out of all eight engine mount bolt holes, which would be kind of a big operation.

Robroy

One issue that remains is that the entire engine+transmission seem to be located about 1/4" or 1/2" further back than they used to be. At first I thought it was just my fancy Autofab transmission mount, but I compared it to the factory mount and the engine+transmission really are 1/4" to 1/2" closer to the rear of the truck than they used to be.

I can't see any way to shift the entire motor and transmission forward 1/4" or 1/2" without making slots out of all eight engine mount bolt holes, which would be kind of a big operation.

- Is there anything critical about the fore/aft position of the engine+transmission, if I'm having a custom driveshaft made (so the length of the driveshaft won't be an issue)?

- Is there any other way to move the entire engine+transmission combo forward 1/4" or 1/2", other than making slots out of the motor mount bolt holes?

Robroy

-

fordman

- 100% FORDified!

- Posts: 22329

- Joined: Sun Aug 28, 2005 8:17 pm

- Location: Kansas, Ottawa

- Contact:

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

that distance probably wont matter. the only two things i can think of are driveshaft length and fan distance to the radiator. but the distance isnt enough to worry about.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

Thanks very much for replying Fordman!

OK, that's what I was hoping for.

Because of this issue, the slots in the transmission mount aren't long enough to fully allow the bolts to pass through--there's a crescent moon shape when I look down through the bolt holes in the rear of the transmission. It sounds like making the slots in the transmission mount a little longer is the proper way to deal with this, and is certainly much easier than updating the bolt holes in the motor mounts (since there are eight of those)!

Does anybody else have additional words of wisdom to help me continue in confidence?

Thanks again Fordman!

Robroy

OK, that's what I was hoping for.

Because of this issue, the slots in the transmission mount aren't long enough to fully allow the bolts to pass through--there's a crescent moon shape when I look down through the bolt holes in the rear of the transmission. It sounds like making the slots in the transmission mount a little longer is the proper way to deal with this, and is certainly much easier than updating the bolt holes in the motor mounts (since there are eight of those)!

Does anybody else have additional words of wisdom to help me continue in confidence?

Thanks again Fordman!

Robroy

-

fordman

- 100% FORDified!

- Posts: 22329

- Joined: Sun Aug 28, 2005 8:17 pm

- Location: Kansas, Ottawa

- Contact:

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

oh i see now why you were worried about it. it is the mount holes that are off.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

Hey Fordman! Yeah that's part of the reason. The mount holes really aren't off, in that they match the factory mount holes (in the factory transmission mount) nicely. But they're off in that they don't line up with the transmission perfectly, since the whole engine+transmission is 1/4" or so pushed back (undoubtedly due to the Autofab engine mounts, since I can't imagine FE blocks would have any variance at all in this respect).

Thanks again Fordman!!!

Robroy

Thanks again Fordman!!!

Robroy

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

With a F250 I don't see the position difference being too big of a deal. The two peice driveshaft is pretty forgiving, but once again, you should be able to get it back to where it was originally. Are the holes in you tranny mount offset for if you flip it around the tranny will be further forward? Just little dumb things like that can screw with you. You may also be able to loosen the tranny mount components and get the slop you need to get the bolts in.

Just thinking out loud since it's been a while since I was under my truck.

Jamie

Just thinking out loud since it's been a while since I was under my truck.

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

Hi Jamie, thanks for replying!

With the engine mounts loose, I tried giving a massive shove to the back of the transmission (to scoot the whole thing forwards), and didn't get far with that. I think the engine mounts are keeping it from going forwards, so I'd have to elongate eight bolt holes to make those mounts accommodating. So I think it might be better to accept the 1/4" to-the-rear location and update the transmission mount to suit it.

The thing is, the slots in the transmission mount don't have too much material left on the aft side. If I took 1/8" out of them, that would only leave about 1/8" of material. I'm thinking it might be a stronger setup if I moved the crossmember back about 1/4", by elongating the crossmember holes in the frame.

Is this method of moving the crossmember back a bad idea for any reason?

Thanks again Jamie for your excellent reply!!!

Robroy

I see! You know, the Autofab tranny mount has slots instead of holes like the factory mount (the slots are where the transmission bolts to the mount, not where the mount bolts to the crossmember). And the slots cover a range from about 3/4" closer to the front of the truck to about 1/8" closer to the rear (compared to the holes in the factory mount). The issue is that the whole engine+transmission assembly is about 1/4" further back than it used to be, so I "run out of slot" on the new transmission mount by around 1/8".Ranchero50 wrote:With a F250 I don't see the position difference being too big of a deal. The two peice driveshaft is pretty forgiving, but once again, you should be able to get it back to where it was originally. Are the holes in you tranny mount offset for if you flip it around the tranny will be further forward?

That's the approach I've been taking, but I don't think I'll get 1/8" out of it.Just little dumb things like that can screw with you. You may also be able to loosen the tranny mount components and get the slop you need to get the bolts in.

With the engine mounts loose, I tried giving a massive shove to the back of the transmission (to scoot the whole thing forwards), and didn't get far with that. I think the engine mounts are keeping it from going forwards, so I'd have to elongate eight bolt holes to make those mounts accommodating. So I think it might be better to accept the 1/4" to-the-rear location and update the transmission mount to suit it.

The thing is, the slots in the transmission mount don't have too much material left on the aft side. If I took 1/8" out of them, that would only leave about 1/8" of material. I'm thinking it might be a stronger setup if I moved the crossmember back about 1/4", by elongating the crossmember holes in the frame.

Is this method of moving the crossmember back a bad idea for any reason?

Thanks again Jamie for your excellent reply!!!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

I just spoke with John at Autofab about the issue. He said that this type of problem is pretty unusual, but that 1/4" isn't "off" enough for him to think there's anything serious going on. His recommendation was to move the transmission mount crossmember back 1/4" by elongating its holes with a die grinder or rat tail file.

He also added that his mounts are extremely precise and rigid, and in comparison, the factory perches are very soft. He said that the factory perches can actually be bent around enough to make up for 1/4".

I'm now wondering if this could be the case. Perhaps due to the location of the engine stand mount holes in the frame, the engine was offset slightly aft by the factory, but they took this as a matter of course and simply shoved it forward (which they were able to do, since the factory engine stands were so soft). Just some speculation.

John said that moving the crossmember back 1/4" shouldn't harm anything, and that he'd deal with it this way. He also recounted a similar procedure to Jamie's, wherein the engine mounts are made loose and the whole deal with pushed around on in an attempt to get things to line up. But he said that final resort is to move the crossmember back.

So that will be my next task!

Thanks very much to everybody for the superb guidance!

Robroy

He also added that his mounts are extremely precise and rigid, and in comparison, the factory perches are very soft. He said that the factory perches can actually be bent around enough to make up for 1/4".

I'm now wondering if this could be the case. Perhaps due to the location of the engine stand mount holes in the frame, the engine was offset slightly aft by the factory, but they took this as a matter of course and simply shoved it forward (which they were able to do, since the factory engine stands were so soft). Just some speculation.

John said that moving the crossmember back 1/4" shouldn't harm anything, and that he'd deal with it this way. He also recounted a similar procedure to Jamie's, wherein the engine mounts are made loose and the whole deal with pushed around on in an attempt to get things to line up. But he said that final resort is to move the crossmember back.

So that will be my next task!

Thanks very much to everybody for the superb guidance!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

Moving the crossmember back 1/4" was easier than I figured it'd be! The crossmember itself was actually "slotted" instead of just having bolt holes, but it was already positioned at one extreme of its "slots." I made some slots in the frame using an air grinder.

Then the transmission lined up PERFECTLY!

With that complete, I performed the aligned steps detailed by Jamie. With the engine stand bolts loose, I shoved around on the engine to make it perpendicular to the frame, then drilled holes to fasten the Autofab transmission mount to the crossmember. I then fastened the transmission to the mount, and with that all secured, returned to the front to tighten up the engine stand bolts. Finally, I loosened the two bolts holding the transmission to the Autofab transmission mount and it DIDN'T KICK TO THE SIDE! SUCCESS!!!

Thanks to Jamie, Stangconv, Dragon, Robert, Dustin, SideOilerFE, Ryan, Lance, and Scott for helping me with this Autofab FE and transmission mount project! It's now complete (or so I think)!

And a special thanks to Jamie for telling me exactly what to do, step by step, to resolve the tricky alignment issue!

I'll post detailed photos of the completely installed mounts when my web server's back up. All my previous photos will re-appear at that time also.

In summary, using the Autofab mounts required these customizations on my truck:

Then the transmission lined up PERFECTLY!

With that complete, I performed the aligned steps detailed by Jamie. With the engine stand bolts loose, I shoved around on the engine to make it perpendicular to the frame, then drilled holes to fasten the Autofab transmission mount to the crossmember. I then fastened the transmission to the mount, and with that all secured, returned to the front to tighten up the engine stand bolts. Finally, I loosened the two bolts holding the transmission to the Autofab transmission mount and it DIDN'T KICK TO THE SIDE! SUCCESS!!!

Thanks to Jamie, Stangconv, Dragon, Robert, Dustin, SideOilerFE, Ryan, Lance, and Scott for helping me with this Autofab FE and transmission mount project! It's now complete (or so I think)!

And a special thanks to Jamie for telling me exactly what to do, step by step, to resolve the tricky alignment issue!

I'll post detailed photos of the completely installed mounts when my web server's back up. All my previous photos will re-appear at that time also.

In summary, using the Autofab mounts required these customizations on my truck:

- Drilled three holes in the crossmember under the engine for the Autofab engine stands. This step was easy because the stands were designed to line up with several of the factory holes, so there was no guesswork or measuring--I just had to drill some extra holes.

- I had to move the transmission support crossmember back 1/4". This may not be necessary on all trucks since the crossmember has slots in it from the factory, and those might provide the necessary slack for other folks.

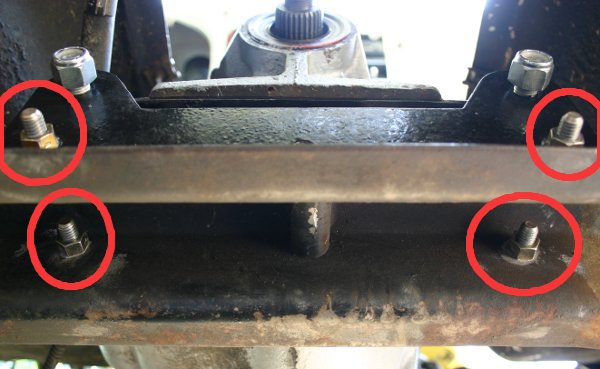

- I had to drill four holes in the transmission support crossmember to fasten the mount. It had a hole that was supposed to be used, optionally, for fastening the mount to the crossmember using the stock, factory bolt. But the hole in the mount was a little "off" to one side, so that option wasn't available to me.

- I had to use Jamie's excellent engine-to-frame alignment procedure to get the engine perpendicular to the frame. Before using Jamie's procedure, the engine appeared (from a bird's eye view) to be rotated somewhat clockwise).

- I had to come up with a new method to secure the metal fuel tubing nearby where it connects the hose segment that leads to the fuel pump. I actually haven't come up with this method yet, but it's quite peripheral to these mounts and doesn't look like it'll be hard to figure out. This step was necessary because the Autofab engine stand occupies the hole that the factory used for a fuel line support clip.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

Here's a photo of the Autofab transmission mount up next to the factory mount. Note that the beautiful finish I put on the Autofab mount got pretty scratched up from all the wrestling it took to get it installed and aligned!

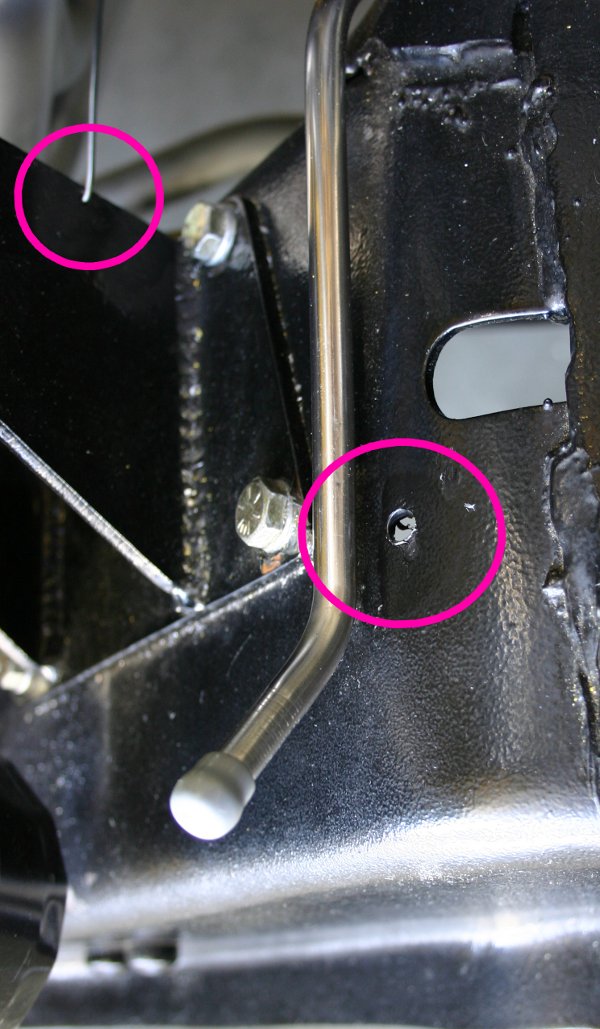

The hole closest to the camera is the one that was used by the crossmember that supported the rear of the transmission. Here it is before I elongated it.

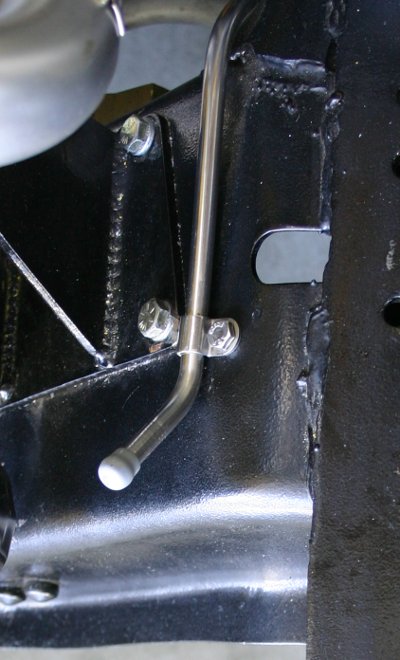

And here it is made a little longer--that's all it took!

Here's the other side, after the same treatment was applied to it.

The transmission, all nicely aligned and fastened down.

Here are the four holes I drilled in the crossmember after aligning the engine+transmission to the frame. This transmission mount is pretty strong now that it's mounted like this!

Thanks again to everybody for helping me solve the problems in this thread!!!

Robroy

The hole closest to the camera is the one that was used by the crossmember that supported the rear of the transmission. Here it is before I elongated it.

And here it is made a little longer--that's all it took!

Here's the other side, after the same treatment was applied to it.

The transmission, all nicely aligned and fastened down.

Here are the four holes I drilled in the crossmember after aligning the engine+transmission to the frame. This transmission mount is pretty strong now that it's mounted like this!

Thanks again to everybody for helping me solve the problems in this thread!!!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: FE and T18/C6 mounts from Autofab, plus frame alignment.

While filling in the details around the engine I've had to do two more customizations to accommodate the Autofab mounts.

The first one involves making a substitute for the factory fuel line clamp. The hole the factory used for this clamp was used by the driver's side Autofab engine stand. So I had to make a new hole and clamp--here are some photos.

This area was problematic without a fuel line clamp there. Not only could the fuel line get to vibrating, but it would yank up if somebody tried to pull a old fuel hose off of it.

I drilled a hole upstream from the fuel line. Also shown in this photo is the tiny hole I drilled in the Autofab engine stand itself to accommodate the clutch return spring (also displaced by the Autofab mount):

Here's the new fuel line clamp in position:

With the clamp in place, that fuel line ain't going NOWHERE. Yup, it ain't goin' NOWHERE.

Robroy

The first one involves making a substitute for the factory fuel line clamp. The hole the factory used for this clamp was used by the driver's side Autofab engine stand. So I had to make a new hole and clamp--here are some photos.

This area was problematic without a fuel line clamp there. Not only could the fuel line get to vibrating, but it would yank up if somebody tried to pull a old fuel hose off of it.

I drilled a hole upstream from the fuel line. Also shown in this photo is the tiny hole I drilled in the Autofab engine stand itself to accommodate the clutch return spring (also displaced by the Autofab mount):

Here's the new fuel line clamp in position:

With the clamp in place, that fuel line ain't going NOWHERE. Yup, it ain't goin' NOWHERE.

Robroy